By Douglas Turner

Lead Restoration Artist

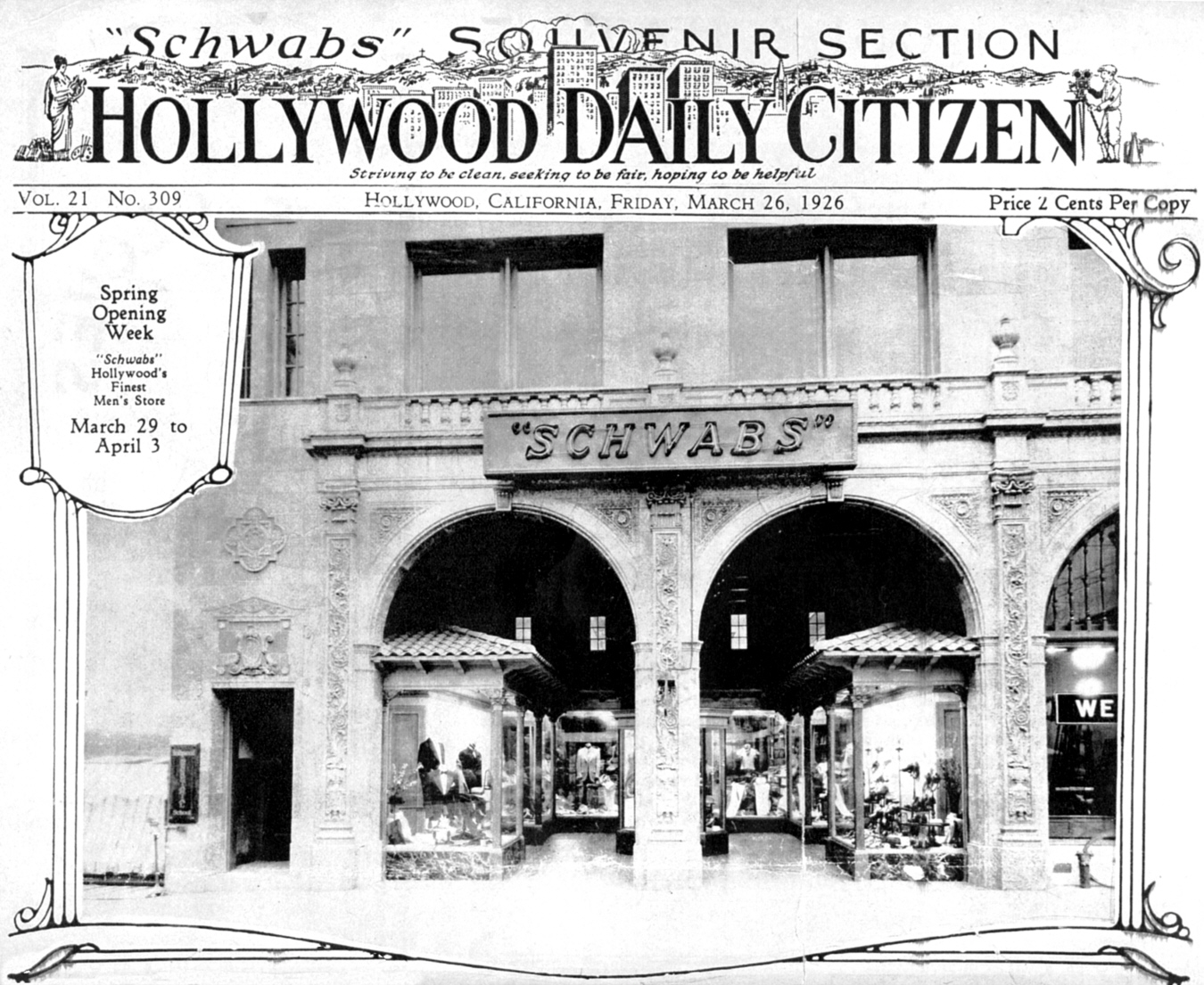

When I first visited the Schwabs Men’s Store Building on the south side of Hollywood Boulevard between Cosmo and Ivar, it was a discouraging site. The once lovely Gladding-McBean terra cotta facade built in 1921 had been badly damaged when a false front and fire escape were added. All of the décorative work that extended out more than a few inches had been unceremoniously smashed away, one column had been stripped to its bare concrete support and another was missing completely. So were most of the arch and the entire west side of the building below fifteen feet. Adding to this, the surface was bristling with metal pins, bolts, and supports and encrusted with spilled tar, mortar and eighty years of road grime.

As the building was being cleaned (by Hollywood Heritage board member Robert W. Nudelman) and we located photographs of its original glory, the potential came alive. The columns and arches had been decorated with floral motifs, vines, leaves, urns and birds. These, as well as geometric designs, were carried up through upper floor and echoed in the frieze along the top. Soon, I began work, with a couple of assistants, on the upper section, while structural work was being done on the lower part by Randy Van Ausdall of Classic Projects. This work included removal of an enormous steel brace, shoring up the missing column and framing out of missing structures, as well as a great deal of work on the interior.

Some of the details of the façade were represented in existing elements that could be repaired then molded in place with a flexible rubber. The mold could then be used to cast new pieces. Other details had to be completely recreated based on photographs (supplied by Hollywood Heritage board member Greg Williams). Organic elements were sculpted in clay while geometric ones were constructed in wood, and then rubber molds were made.

Small repairs were made in place with epoxy putty but many large areas had to be completely fabricated. Replacement pieces were cast in Forton MG, which technically is a Glass Fiber Reinforced Modified Gypsum, that is, a very hard plaster, (hydrocal 95 f.g.r.) modified to withstand the weather, and strengthened with fiberglass. The material– three powders and two liquids–is carefully measured and mixed then poured or brushed into a rubber mold and allowed to set. This is backed up and strengthened with more Forton MG and multiple layers of fiberglass. The resulting pieces were light weight and strong and could be cut, drilled and sanded as needed.

In a makeshift workshop inside the building, castings were made by Amy Higgins and Lowell Turner while I prepared the surfaces and installed the finished castings. The greatest challenges were in replacing the missing arch and western-most column, and some creative license was taken in creating the window on the west side and blending the necessary fire safety connections and panels into the structure. The terra cotta continued into the interior of the façade and was cleaned and repaired as well.

As the installation of pieces continued, and the storefronts, doors and windows came into place, we began developing paint techniques to blend the existing terra cotta, the repairs, and the new construction into a cohesive whole. Considerable experimentation was required to find the best system to match not only color but texture and pattern. To maintain the individuality and supple variation of the blocks that give the facade life and character, Amy Higgins was required to paint each block individually with multiple applications of colored glazes applied by sponge, brush and modified rollers. She also did this to mask existing seismic bolts and plates on the façade.

As we neared completion, even my crew and I were finding it difficult to distinguish our work from the original that, of course, was the goal all along.